Specialized manufacturer of water quality related apparatuses such as pH meter, pH Neutralizer.

- HOME

- English_TOP

- Chemical diaphragm pump and submersible pump, introduce of handy pump

- self-contained corrosion-resistant resin pump "CEMPUM ACE"

Excellent corrosion resistance, compact

self-contained corrosion-resistant resin pump "CEMPUM ACE"

|

High corrosion resistance is achieved by using polypropylene containing carbon fibers.

|

|

Advantages

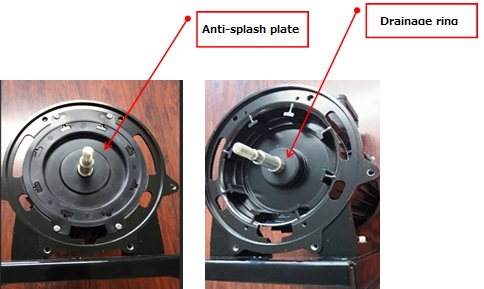

| ・A splash prevention plate prevents the motor from entering even when the mechanical seal leaks. |

| ・Use of new materials for casings and excellent corrosion resistance! |

| ・A compact design requires less installation space. |

| ・Low-noise motors and quieter operation sounds. |

| ・Replacement of the mechanical seal is also easy and maintenance is necessary. |

Excellence in self-respiration performance

Despite its compact body, it exhibits excellent self-respiration capabilities.

|

Note: For self-breathing at 5 m, atmospheric pressure is the condition. |

[Capability] ・At 50 Hz ・At 60 Hz |

High corrosion resistance/long life

The pumping section uses CFRPP and GFRPP, the motor shaft is made of SUS316, and the inner screws are made of titanium, SUS316, and other materials, making it highly corrosion resistant.

It can be used in a wide range of fields, including fresh water, sea water, and some chemical solutions.

|

|

*High corrosion resistant body ・Pump section made of corrosion-resistant material |

Economic

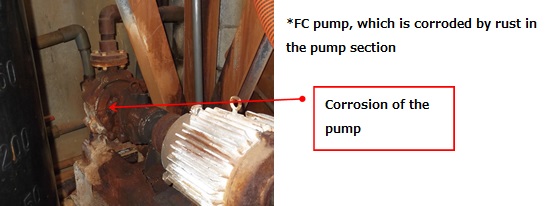

At present, FC pumps have a short life and a short replacement time due to rust generation.

Since CEMPUM ACE is made of resin, it is easy to disassemble, assemble, and maintain without rusting.

Safety design

Even if fluid leaks during the life of the mechanical seal, which is a consumable, the splash prevention plate is equipped as standard, so it does not splash on the motor side and protects it from electrical leakage.In addition, the motor shaft is equipped with a drainage ring, which can be double-sided.

|

In the event of a motor overload, a protective device works to prevent the motor from burning, making the design safe. |

|

Example of introduction

Bag filter unit using Cempum Ace

The filtration capacity is 5 m3/hr.It is compact and is suitable for incorporation into various unit products.

Applications

| ・To the water treatment plant equipment. |

| ・Transfer of seawater related to fisheries. |

| ・Incorporation of surface treatment-related equipment. |

| ・It is also suitable for use in corrosive liquids and atmospheres. |

Specifications

| Model | CSP-40-50.4T | CSP-40-60.4T |

| Diameter (mm) | 40 | |

| Frequency (Hz) | 50 | 60 |

| Voltage (V) | Three-phase 200 | |

| Rated output (W) | 400 | |

| Maximum discharge (L/min) | 120 | 110 |

| Maximum lifting height (mH) | 8 | 10 |

| Mass (Kg) | 11.0 | |

| Liquid temperature | 0~40 | |

Wetted materials

| Handling liquid | Liquid quality | Fresh water, chemical solutions, and sea water | |

|

Pump section |

Structure | Impeller | Semi-open |

| Shaft seal | Mechanical seal | ||

| Wetted materials | Impeller | GFRPP | |

| Casing | CFRPP | ||

| Casing cover | CFRPP | ||

| Mechanical seal | Ceramic×Carbon | ||

| Shaft | SUS316 | ||

| Internal screws | SUS316/Titanium | ||

| Packing | EPDM | ||

| Splash prevention cover | PP | ||

| Motor | Full-closed fan outdoors | Linear motion | |

Catalogue

|

|